Footwear Development

Reverse Tech Pack

The Goal

01

The goal of this project was to create a full tech pack of a shoe that already exists by dissecting it (literally cutting it into pieces). In the end, I created a tech pack a factory could use to build the same shoe I had in my hand when I started and in the process gain the skill set and knowledge of how footwear development works within the industry.

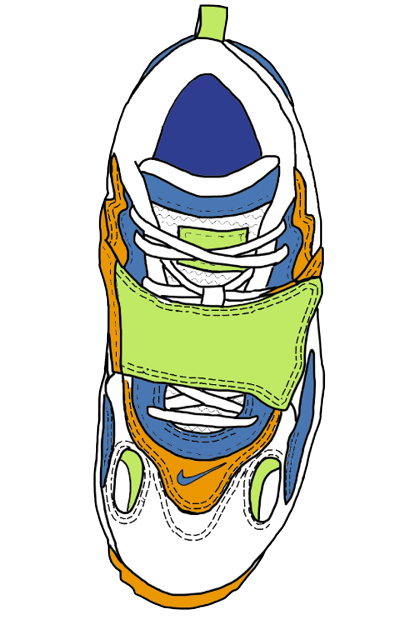

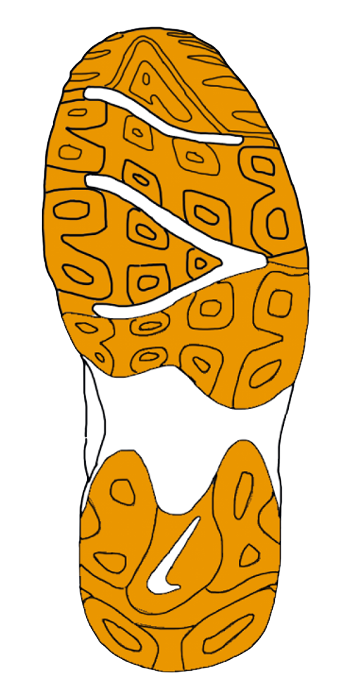

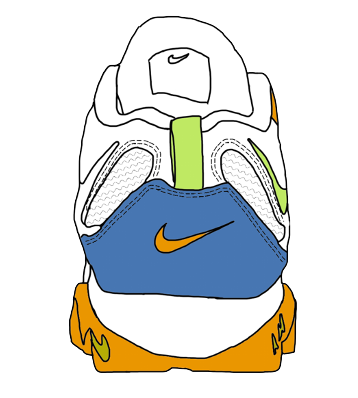

To see exactly how each part of the shoe was designed and put together, the next step involved my cutting the shoe apart into its critical components. Once I had all the photos I needed, I created 3D drawings of all the crucial views including medial and lateral.

Once all the drawings were complete, it was time to start in on the details of how the shoe is made. First I labeled every part of the shoe, which is necessary to create the Bill of Materials (BOM). Below is an example of the lateral view callouts.

The Process

02

Other components of the tech pack include shell and tooling patterns, upper layering details and measurements.

Final Product

03

Throughout the process of creating a tech pack in reverse, I gained valuable knowledge about the footwear development process. From how to communicate with factories overseas to leaving no detail unturned or open to interpretation, the project fueled my enthusiasm for product development.

For a closer look at the final product, please download the PDF below.

First I picked a shoe that had enough parts and character to make this an interesting but difficult task. I chose the Nike Air Max Speed Turf that had a combination of lifestyle and sportswear.

In order to model the shoe using CAD, I took photos of the shoe from every angle. Since this was a ‘reverse’ tech pack, this mimicked the process of creating full CAD models for the manufacturers to follow.